This film is gas barrier film for food storage(2times more)

![]() Decomposition prevention of food by Oxygen

Decomposition prevention of food by Oxygen

![]() Gas transmissivity is decrease 99% than general food package film

Gas transmissivity is decrease 99% than general food package film

![]() Transparency preservation

Transparency preservation

![]() Oxygen Transmission Rate at 23 ℃

Oxygen Transmission Rate at 23 ℃

![]() Water Vapor Transmission Rate at 23 ℃

Water Vapor Transmission Rate at 23 ℃

![]() Test-lab: SKC (Korea) research with Fraunhofer (Germany) R&D

Test-lab: SKC (Korea) research with Fraunhofer (Germany) R&D

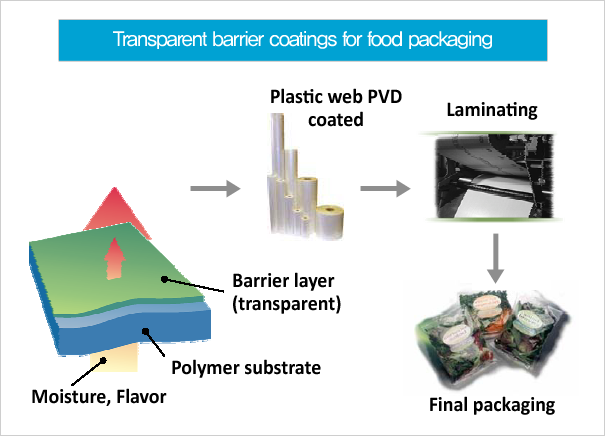

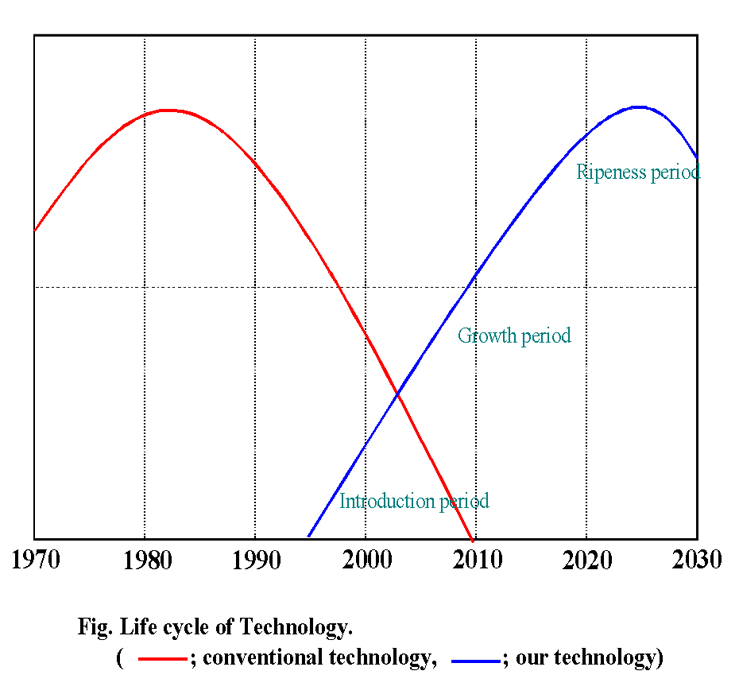

This technology is related to manufacturing technology of new film with good barrier gas and organic substance. barrier film is actively adopted to packaging in food/ beverage/ medical products/ and industrial parts. In particular, high barrier effect on leak of gas, smell and vapor in substitution packaging and beverage packaging or vacuum packaging, preventing from microorganism growth, content oxidation, and fragrance & solvent. However, the pre-existing products are manufactured by accumulating various polymers, which has made it thicker and complicated process and bad gas barrier effect. Besides, polymer barrier film from molecule level and some materials have been not appropriate to manufacture food & beverage packaging, or not approved by authorities. To overcome such weakness requires new manufacturing method of film with very excellent barrier effect at lower prices. Development of packaging film with good barrier effect, is expected to make great ripple effect on the related areas such as food & logistics, by increasing the food storage.

![]() Needs of characteristics of the pre-existing barrier

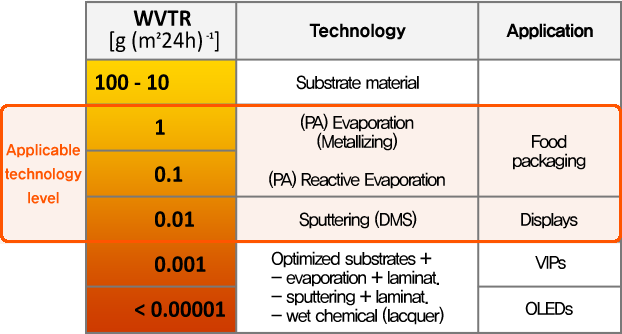

OTR < 1cc/m2 / Day (PET-RHB-10% expensive PET),

WVTR<1 g/m2 /Day (PET-RHB-10)

Needs of characteristics of the pre-existing barrier

OTR < 1cc/m2 / Day (PET-RHB-10% expensive PET),

WVTR<1 g/m2 /Day (PET-RHB-10)

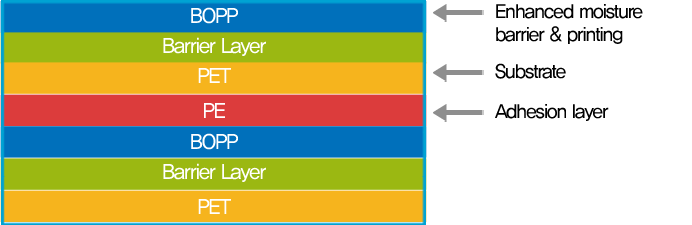

![]() Excellent Adhesion layer

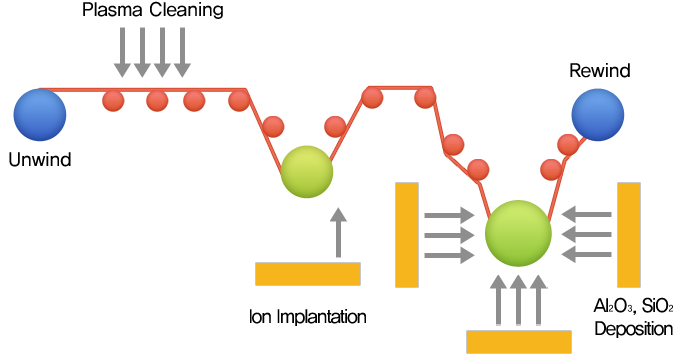

Adhesion layer effect increased, after plasma treatment.

Excellent Adhesion layer

Adhesion layer effect increased, after plasma treatment.

![]() Excellent vacuum packaging characteristics

Whether automatic vacuum packaging is enabled

Excellent vacuum packaging characteristics

Whether automatic vacuum packaging is enabled

Separate facilities required for treatment fo PE/PP Laminating and FINISH SURFACE

![]() No materials deformation due to low temp. process

No materials deformation due to low temp. process

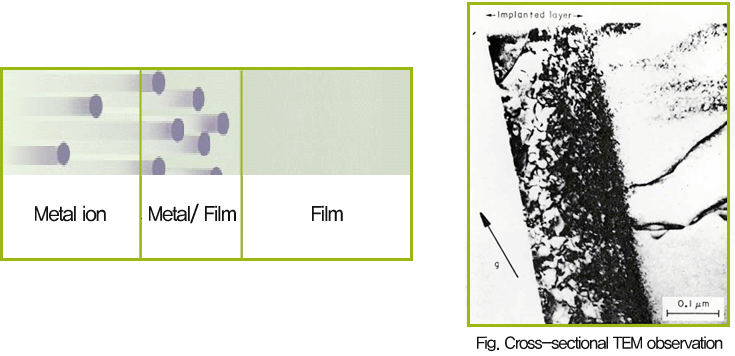

![]() Very high strength of Adhesion layer due to formed ion injection layers (Hair Crack minimized)

Very high strength of Adhesion layer due to formed ion injection layers (Hair Crack minimized)

![]() No oxidation or damage on surface

No oxidation or damage on surface

![]() Adjustable depth of surface less than micron

Adjustable depth of surface less than micron

![]() Currently used bottle-type save container applied

Currently used bottle-type save container applied

![]() To increase usability and long-term storage, first changed to vinyl packaging

To increase usability and long-term storage, first changed to vinyl packaging

![]() Changed to bottle type again, due to dioxin detected in vinyl packaging

Changed to bottle type again, due to dioxin detected in vinyl packaging

![]() Fundamental removal of dioxin detect

Fundamental removal of dioxin detect

![]() Great decrease in oxygen transmission rate & moisture transmission rate

Great decrease in oxygen transmission rate & moisture transmission rate

![]() Barrier Film is changed to multi layers (Adhesion layer technology required)

Barrier Film is changed to multi layers (Adhesion layer technology required)

If this item developed and completed, applicable items are as follows:

![]() Food packaging

Food packaging

![]() Meat & dairy products packaging

Meat & dairy products packaging

![]() Medical products packaging

Medical products packaging

![]() Industrial products packaging

Industrial products packaging

![]() Others

Others

78-6, Munpyeong-dong, Daedeok-gu, Daejeon, Korea Uniplatek / TEL.+82-42-867-7685 / FAX.+82-42-867-7688 / E-mail.ceo@uniplatek.com

COPYRIGHT(C) 2014 UNIPLATEK ALL.RIGHTS RESETVED.