Coated with heat-resisting polymer film & features heating Precise technology & cutting-edge carbon fiber surface heater.

![]() CARBON FIBER & CNT synthetic process applied

CARBON FIBER & CNT synthetic process applied

![]() conductive fiber designs & electrode placement process applied

conductive fiber designs & electrode placement process applied

![]() P/U series of thin layer insulating material laminating process applied

P/U series of thin layer insulating material laminating process applied

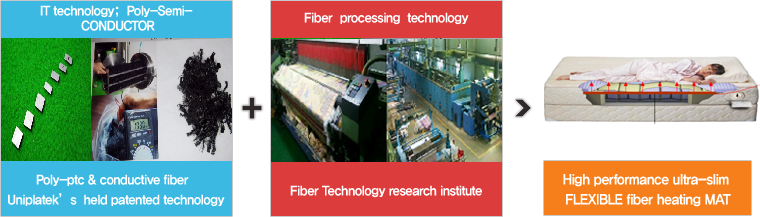

![]() POLY-SEMI CONDUCTOR manufacturing technology

POLY-SEMI CONDUCTOR manufacturing technology

![]() Power-saving, over-hating resistant PTC active element adopted / applied

Power-saving, over-hating resistant PTC active element adopted / applied

![]() Heating treatment for CARBON FIBER conductive function technology

Heating treatment for CARBON FIBER conductive function technology

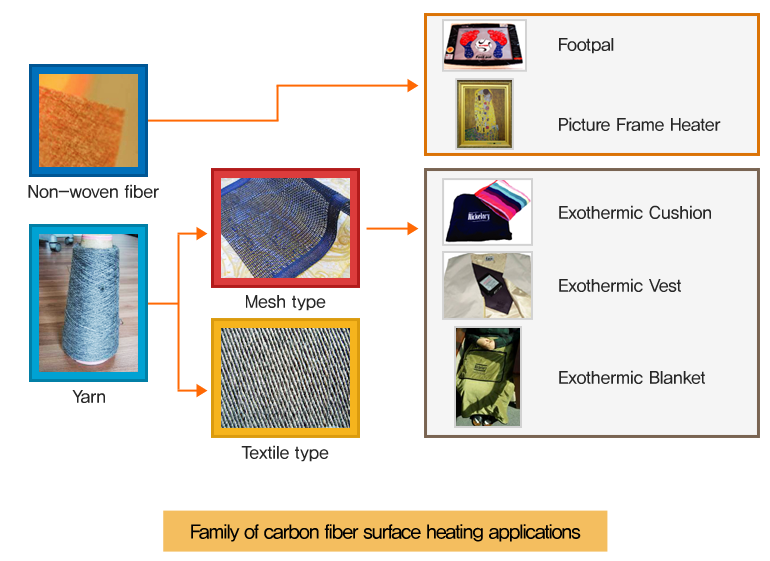

![]() Through spinning/weaving technology, conductive fiber design & electrode placement process applied

Through spinning/weaving technology, conductive fiber design & electrode placement process applied

![]() Consumers’ needs are considered in designs of finished product MAT

Consumers’ needs are considered in designs of finished product MAT

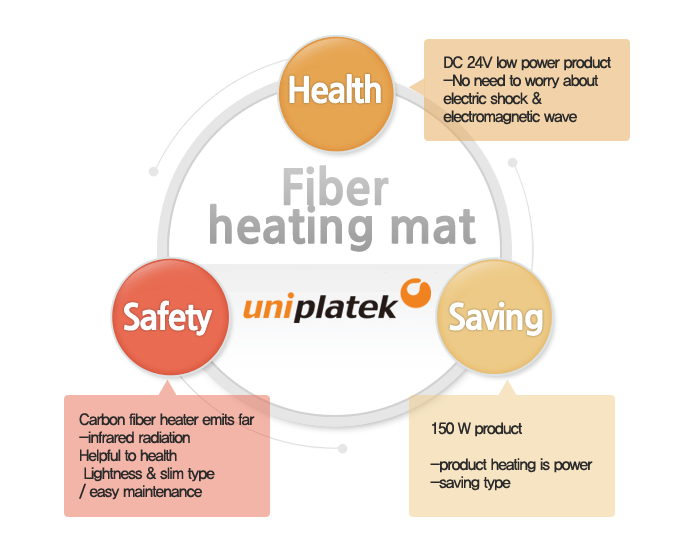

Power-saving type, Over-heating resistant PTC active element adopted/applied. Product manufacturing with over-heating resistant & energy saving type technology conversion Prototype made

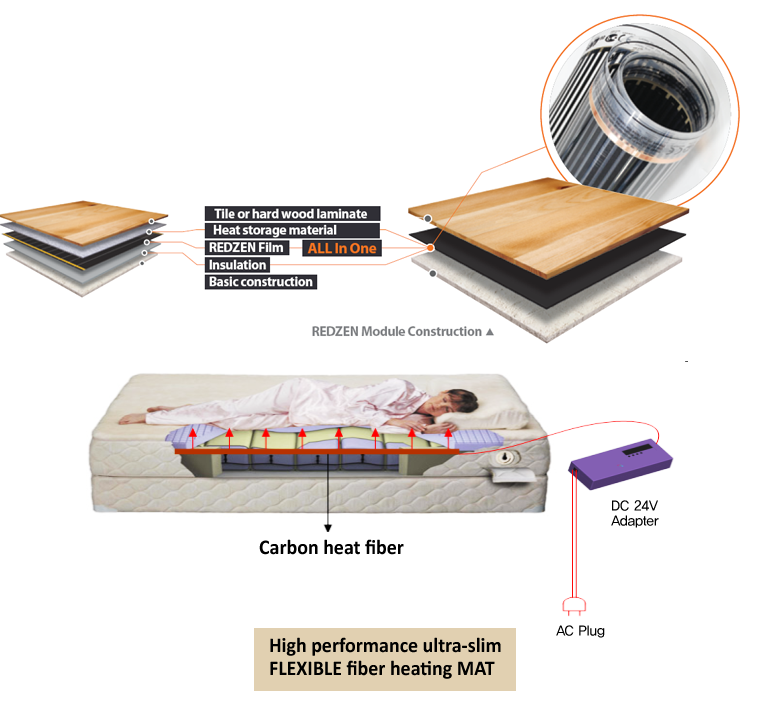

| Specification | 1000 mm in width, 3 METER in length, Heater thickness within 3mm |

|---|---|

| Performance | Heating temperature 35 degree or over, temperature deviation within ±5℃,Power consumption within 150W/M2within - Purpose: Saving type fiber carbonized heater for heating |

| Feature | Ultra-slim fiber heater without electromagnetic interchanging |

Conductive type carbonized heating resistance material manufacturing - Power-saving effect enhanced through structured designs (Power-saving type150W/m2 , thermal conversion efficiency 90 %) - Manufactured fiber heater with heating resistance materials with flexibility & durability

DC 24v/12v power without electromagnetic interchanging Insulation coating material P/U laminating process technology

Conductive power like metal power or thin layer type claddings are used electrode, for mechanical fastening on the bonding sections with conductive fiber and to have arc created & carbon resistant

| Chinese Patented | NO.201010193737.1 KP1807 Application date 2010.08.10 |

|---|---|

| U.S.A. Patented | US12/872.874 Application date; Aug. 30 2010 U.S.A. international Patented Registration date;2013.11.02 |

| KoreanPatented | 10-1129251 Registration date 2012.01.31 |

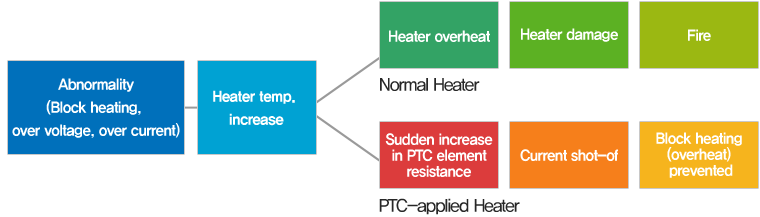

PTC(Positive Temperature Coefficient ) Temperature self-induction type active element -Not ceramic, but polymer type semi-conductor element Module manufacturing process - Electrode connector are continuous multi-process to ensure the automated 15 processes and high productivity implementations Features -Automatic conversion in phase at over constant temperature (Curie temperature) Competitiveness -Uniqueness in element manufacturing technology development & affordable production cost

78-6, Munpyeong-dong, Daedeok-gu, Daejeon, Korea Uniplatek / TEL.+82-42-867-7685 / FAX.+82-42-867-7688 / E-mail.ceo@uniplatek.com

COPYRIGHT(C) 2014 UNIPLATEK ALL.RIGHTS RESETVED.